- Sinomet

- Foshan, Guangdong

- 15~30 Days

- 40 HQ per month

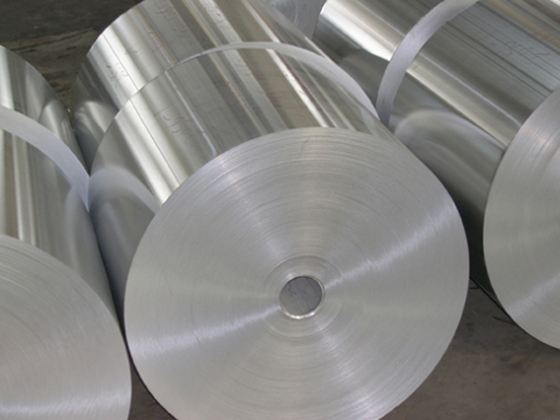

1. Lightweight: Aluminum is a lightweight metal, making aluminum coils easy to handle and transport.

2. Corrosion-resistant: Aluminum is naturally resistant to corrosion, which means that aluminum coils can withstand exposure to moisture and other environmental factors.

3. Durable: Aluminum coils have a long lifespan and can withstand harsh weather conditions.

4. Versatile: Aluminum coils can be used in a variety of applications, including roofing, siding, gutters, and HVAC systems.

5. Cost-effective: Aluminum is an affordable material, which makes aluminum coils a cost-effective solution for many projects.

6. Recyclable: Aluminum is a highly recyclable material, which means that aluminum coils can be recycled and reused.

Aluminum coil is typically made of pure aluminum or aluminum alloy, which is a mixture of two or more metals. The exact contents of aluminum coil can vary depending on the specific alloy used, but some common alloying elements include: 1. Copper: Copper is often added to aluminum alloys to increase their strength and hardness.

2. Magnesium: Magnesium is added to aluminum alloys to improve their strength and corrosion resistance.

3. Zinc: Zinc is added to aluminum alloys to improve their strength and toughness.

4. Manganese: Manganese is added to aluminum alloys to improve their strength and resistance to corrosion.

5. Silicon: Silicon is added to aluminum alloys to improve their strength and machinability.

6. Iron: Iron is sometimes added to aluminum alloys to improve their strength and hardness. The exact composition of aluminum coil will depend on the specific application and performance requirements of the product.

Aluminum coil is a versatile material that can be used in a wide range of applications. Some common uses of aluminum coil include:

1. Roofing: Aluminum coil is often used as roofing material due to its lightweight, durability, and resistance to corrosion.

2. Siding: Aluminum coil can also be used as siding material for buildings due to its durability and resistance to weathering.

3. Gutters: Aluminum coil is commonly used to make gutters due to its ability to resist rust and corrosion.

4. HVAC: Aluminum coil is often used in heating, ventilation, and air conditioning (HVAC) systems due to its ability to transfer heat efficiently.

5. Automotive: Aluminum coil is used in the automotive industry to make parts such as radiators, condensers, and evaporators due to its lightweight and corrosion resistance.

6. Electronics: Aluminum coil is used in the electronics industry to make components such as heat sinks and circuit boards due to its thermal conductivity and machinability.

Overall, aluminum coil is a popular material for many different applications due to its strength, durability, and versatility.

We're factory.Production,sales and transportation intergration....more