- Sinomet

- Foshan, Guangdong

- 15~30 Days

- 40 HQ per month

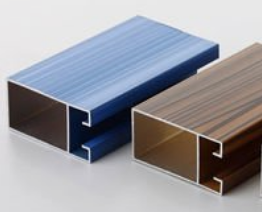

Aluminum alloy extrusion bar is a versatile, strong, lightweight, corrosion-resistant, and customizable material that can be used in a wide variety of applications.

Aluminum alloy extrusion bar is a type of metal bar that is made by forcing molten aluminum through a die to create a specific cross-section. The most common type of aluminum alloy used for extrusion is 6063, which is a strong and corrosion-resistant alloy. Other common types of aluminum alloy used for extrusion include 6061, 2024, and 7075.

The contents of aluminum alloy extrusion bar vary depending on the specific alloy used. However, all aluminum alloy extrusion bars contain the following elements:

* Aluminum (Al): The main component of aluminum alloy extrusion bar, aluminum is a lightweight metal that is strong, ductile, and corrosion-resistant.

* Magnesium (Mg): Magnesium is added to aluminum alloy extrusion bar to improve its strength and machinability.

* Manganese (Mn): Manganese is added to aluminum alloy extrusion bar to improve its strength and toughness.

* Silicon (Si): Silicon is added to aluminum alloy extrusion bar to improve its strength and corrosion resistance.

* Copper (Cu): Copper is added to aluminum alloy extrusion bar to improve its strength and conductivity.

In addition to these elements, aluminum alloy extrusion bars may also contain trace amounts of other elements, such as iron, titanium, and zinc.

The properties of aluminum alloy extrusion bar are determined by the type of alloy used and the heat treatment process used to produce it. For example, 6063 aluminum alloy extrusion bar is typically available in the following tempers:

* O: Soft

* T4: Solution heat treated and naturally aged

* T6: Solution heat treated and artificially aged

The O temper is the softest temper and is typically used for applications where machinability is important. The T4 temper is a stronger temper that is typically used for applications where strength and ductility are important. The T6 temper is the strongest temper and is typically used for applications where high strength and corrosion resistance are important.

We're factory.Production,sales and transportation intergration....more