- Sinomet

- Foshan, Guangdong

- 15~30 Days

- 40 HQ per month

1. Precision: CNC machining offers a high degree of precision and accuracy, ensuring that the aluminum profiles are machined to exact specifications.

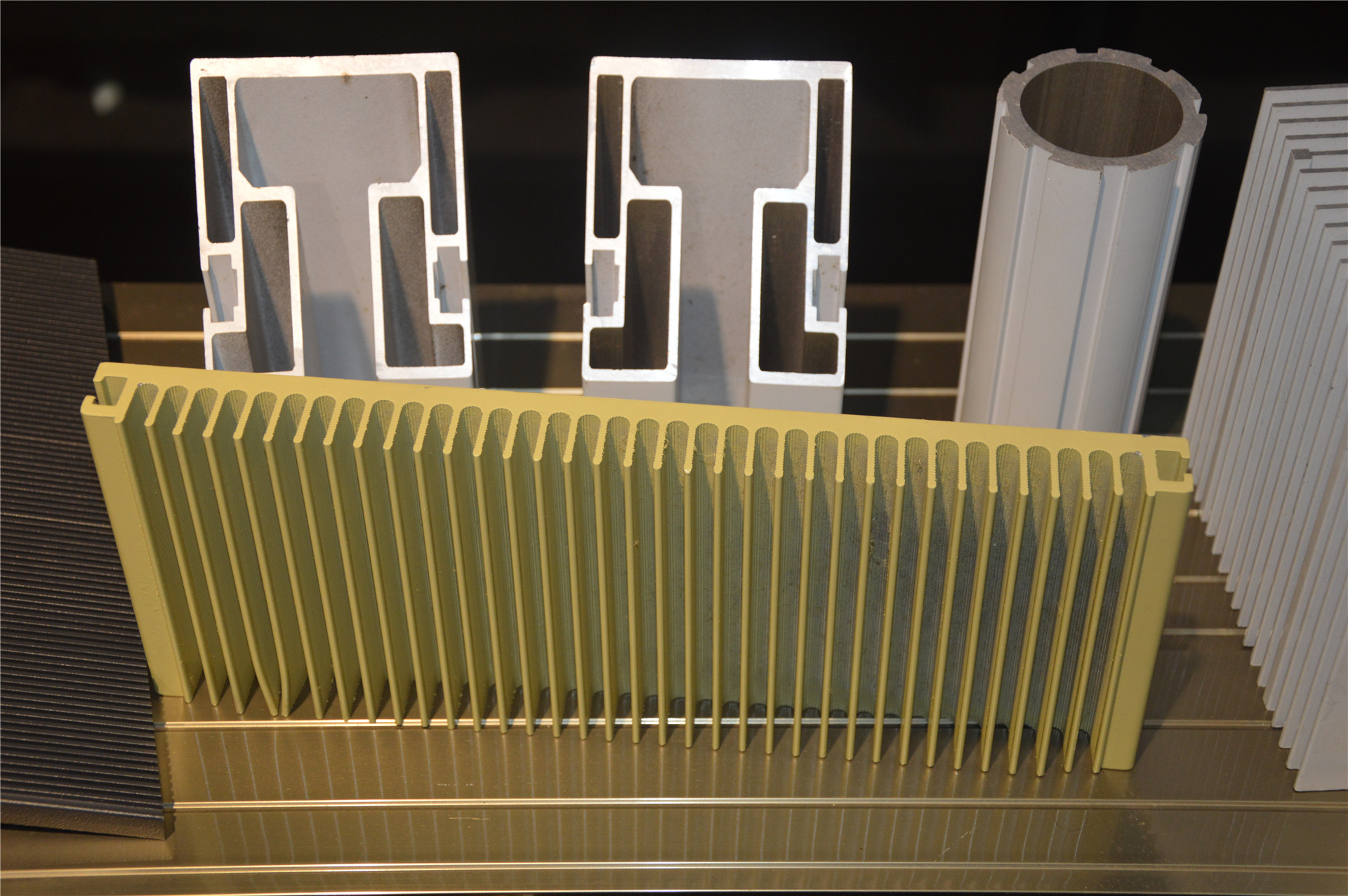

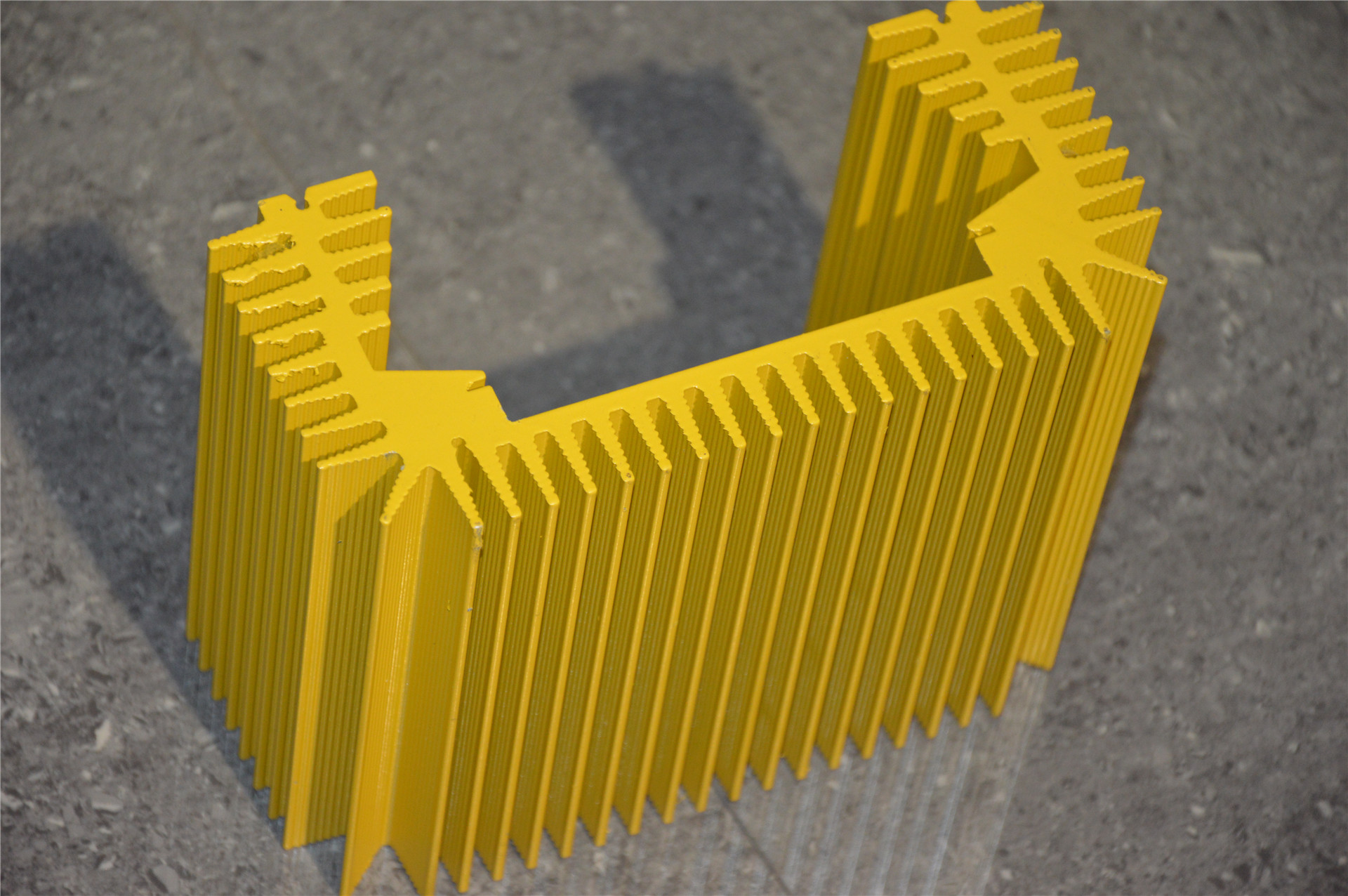

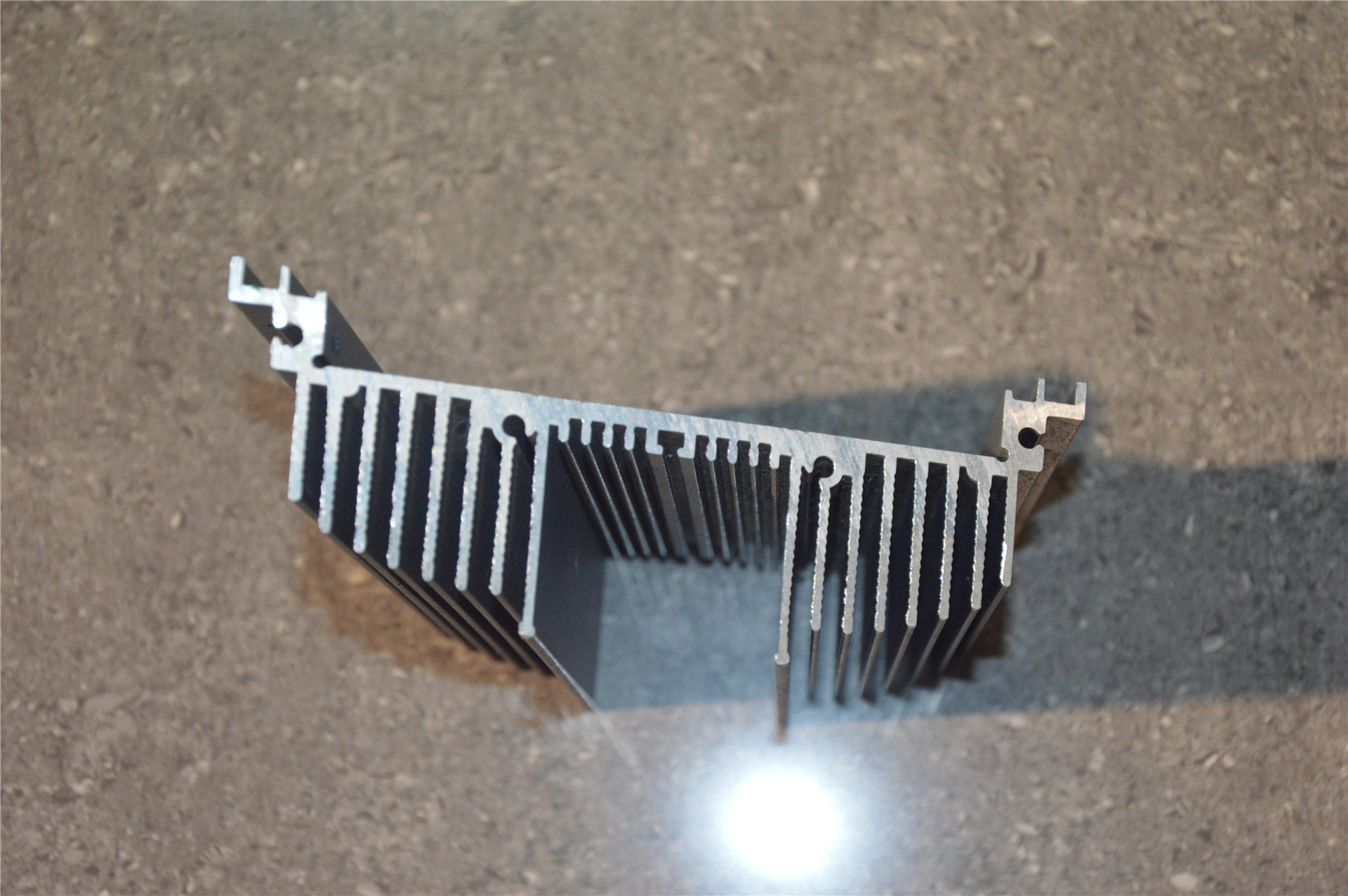

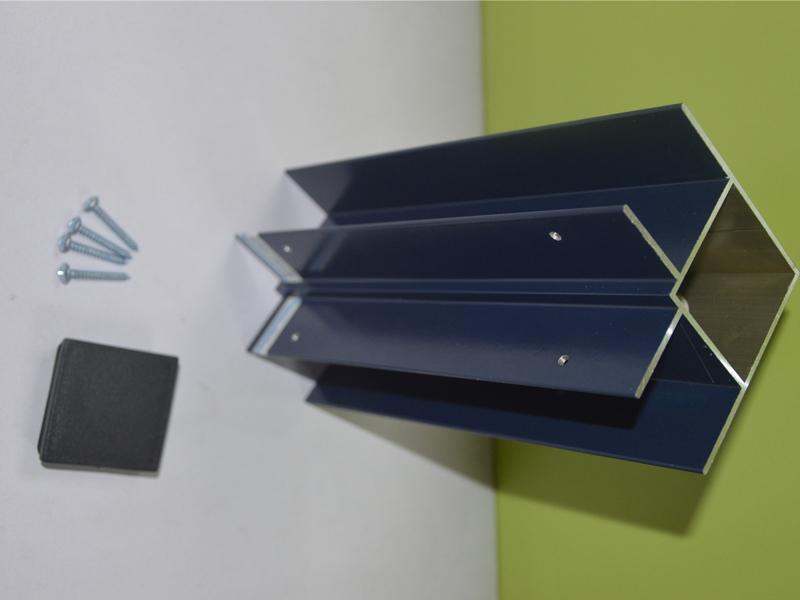

2. Versatility: CNC machines can be used to create complex shapes and designs, making them ideal for manufacturing a wide range of aluminum products and parts.

3. Efficiency: CNC machining is a highly efficient process that can produce high volumes of aluminum profiles quickly and consistently.

4. Cost-effective: CNC machining is a cost-effective process that reduces material waste and labor costs, resulting in lower overall production costs.

5. Consistency: CNC machining produces consistent results, ensuring that each aluminum profile is identical to the next.

6. Quality: CNC machining offers high-quality finished products that meet or exceed industry standards.

7. Customization: CNC machining allows for easy customization of aluminum profiles, making it possible to create unique designs and shapes.

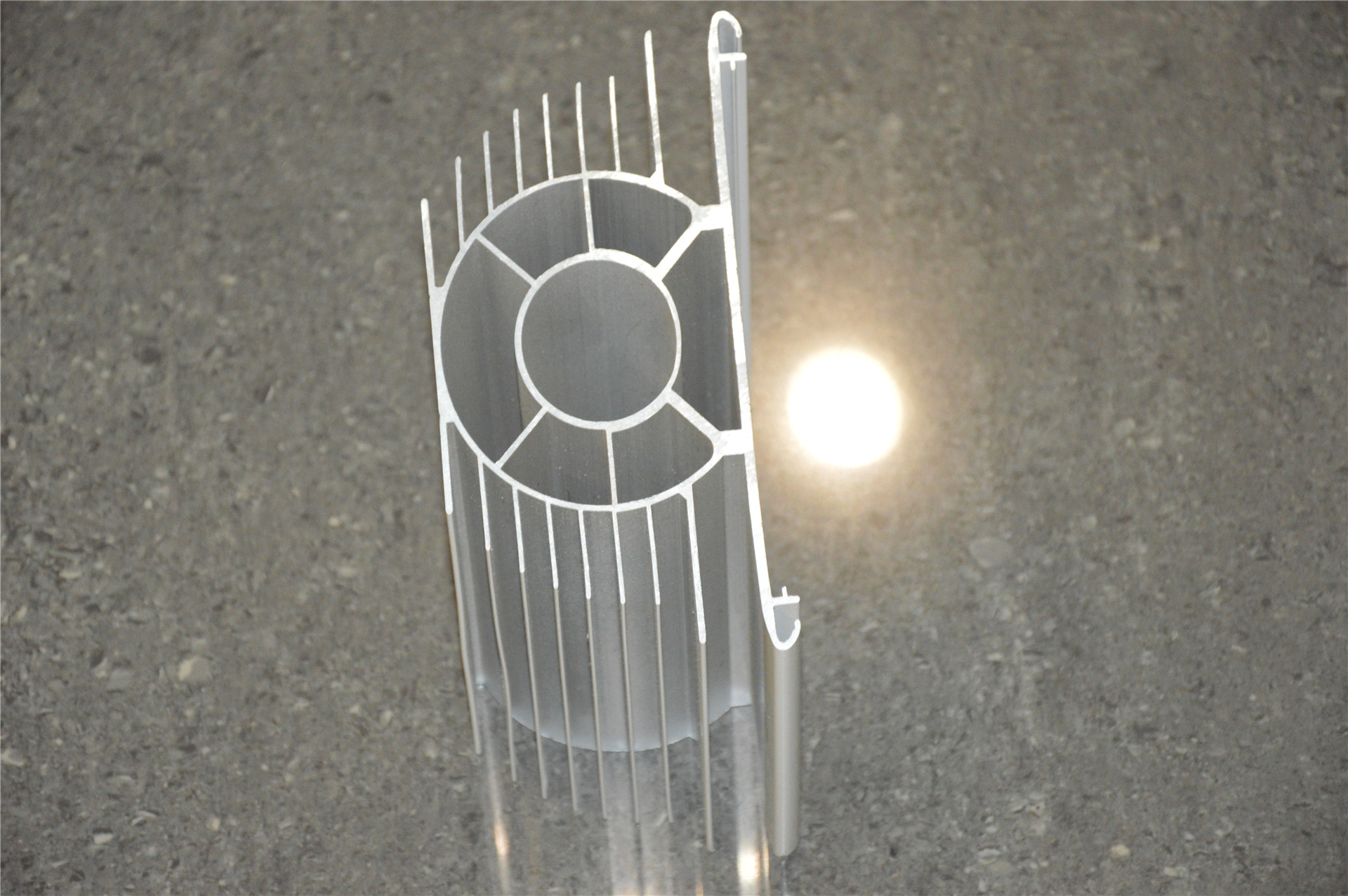

CNC machining aluminum profiles is a common process in manufacturing aluminum products and parts. Aluminum is a lightweight and durable material that can be easily machined to create complex shapes and designs.

Here are the steps involved in CNC machining aluminum profiles:

1. Design: The first step is designing the profile using computer-aided design (CAD) software. The designer creates a 3D model of the part, which is then converted into a machine-readable code.

2. Material selection: The next step is selecting the right type of aluminum material for the profile. The choice of material depends on the specific application and performance requirements.

3. CNC programming: The machine-readable code is then converted into CNC machine instructions using computer-aided manufacturing (CAM) software. The instructions include information on tool paths, cutting speeds, and other machining parameters.

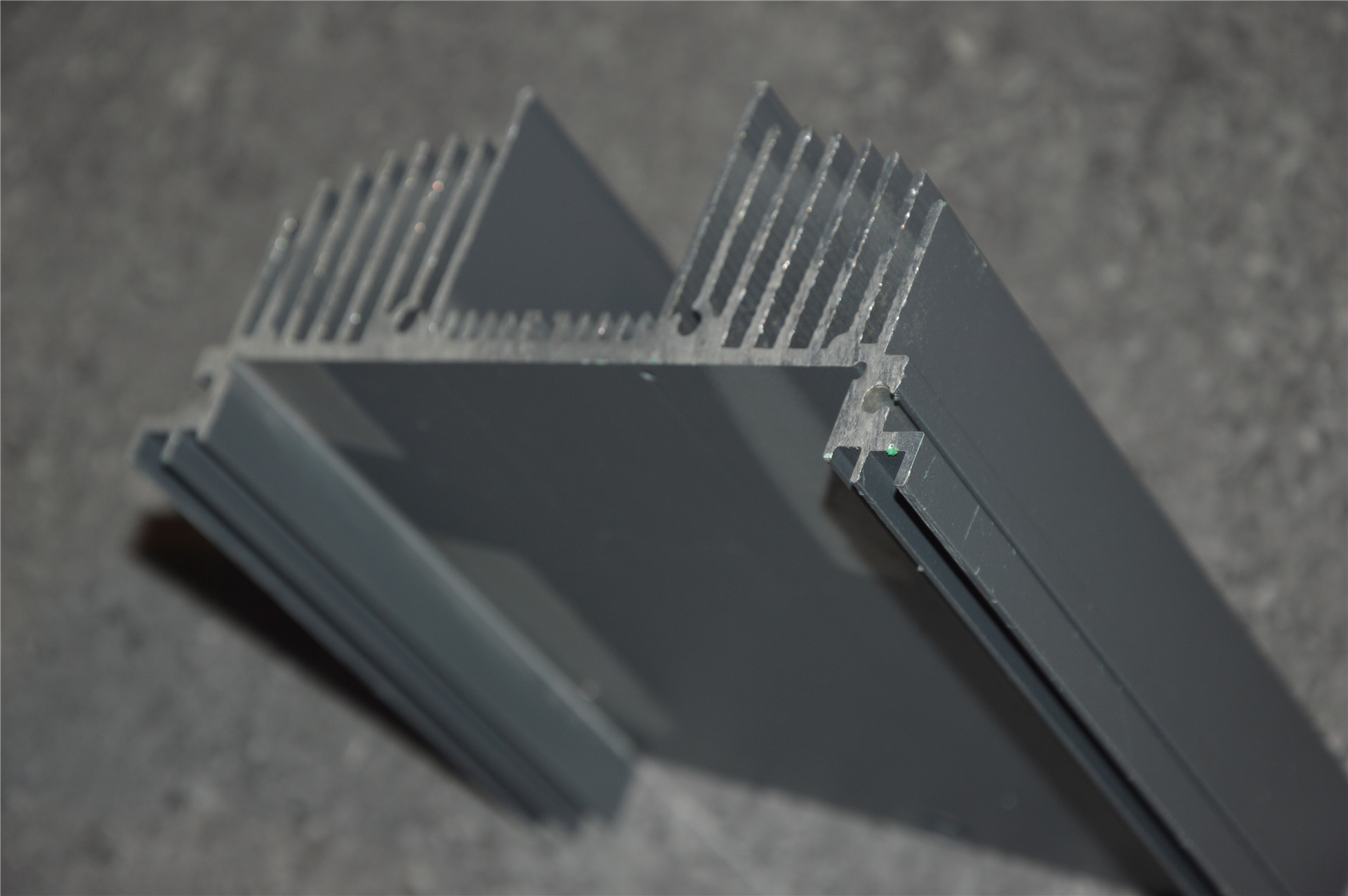

4. CNC machining: The CNC machine is then set up with the appropriate cutting tools and the aluminum material is loaded onto the machine. The machine then follows the programmed instructions to cut the aluminum into the desired profile.

5. Finishing: After the machining process is complete, the aluminum profile is inspected for quality and any necessary finishing steps are performed. These may include deburring, sanding, polishing, or anodizing.

CNC machining aluminum profiles offers a high degree of accuracy and repeatability, making it a popular choice for manufacturing aluminum products and parts.

We're factory.Production,sales and transportation intergration....more